Description

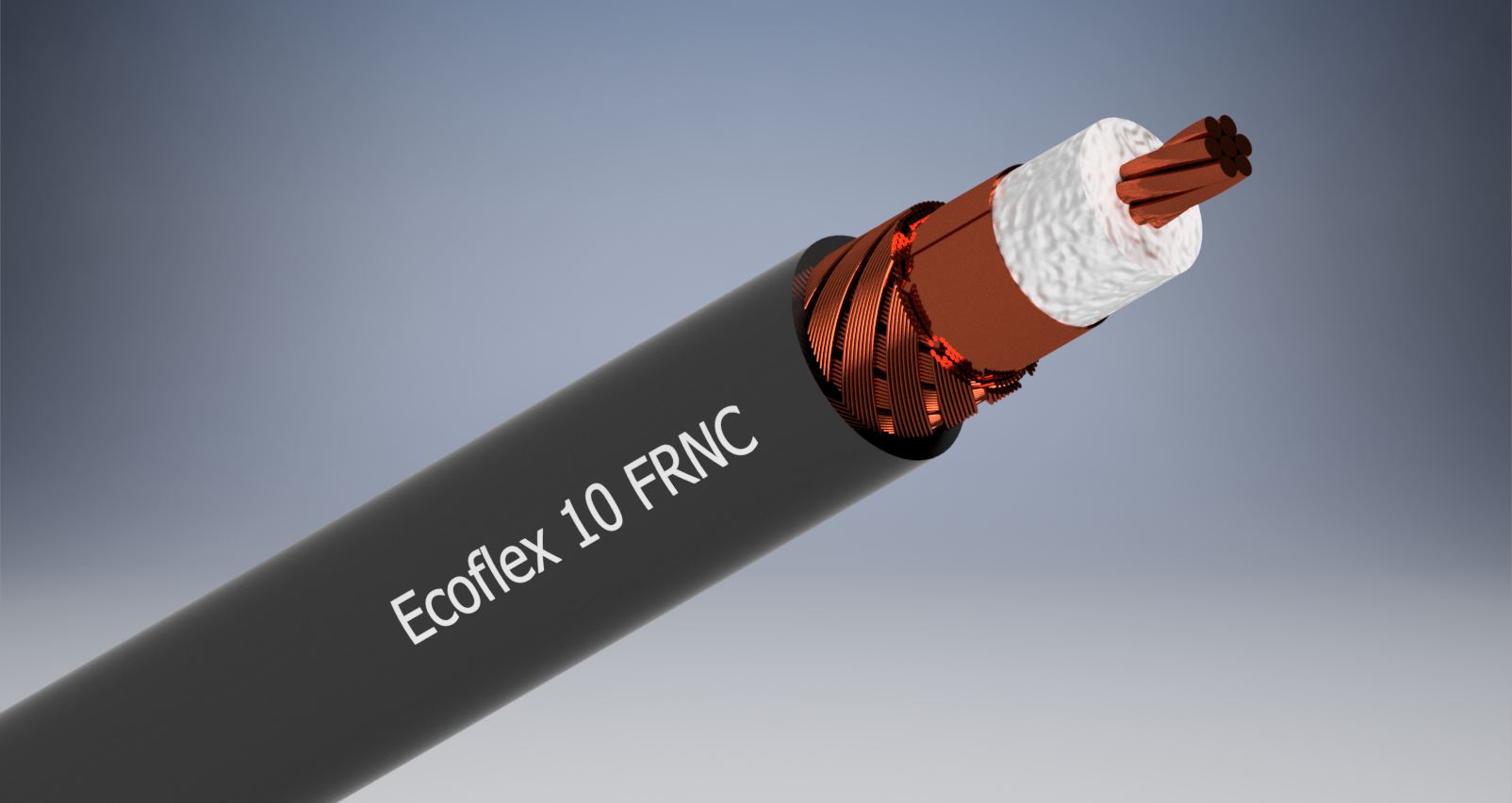

Ecoflex 10 FRNC is a flexible and very low loss 50 ohm coaxial cable for the frequency range up to 6 GHz. State-of-the-art production processes and the use of a low-loss PE-LLC dielectric with a gas content of more than 70% enable low attenuation values, which set standards for flexible coaxial cables of this dimension. The high flexibility of Ecoflex 10 FRNC is ensured by a 7-core strand core conductor made of low-oxygen copper. The inner conductor is compressed in a special operation, calibrated and then pre-coated to achieve good damping and adaptation values.

Another advantage of Ecoflex 10 FRNC its double shielding: an overlapping copper foil and an additional shield braiding of bare copper wires with 75 % coverage ensure a high screening attenuation of > 90 dB at 1 GHz.

The jacket of Ecoflex 10 FRNC is made of a special thermoplastic copolymer (FRNC: Flame Retardant Non Corrosive). Due to this flame retardant and halogen-free material the cable has a low fire load, low flame propagation and limited smoke emission.

The amount of toxic and corrosive gases is considerably reduced during combustion. With the fire protection rating Ecoflex 15 FRNC is approved for

installation in public buildings.

We like this cable – better construction and more flexible than CNT400 and flame retardant low halogen so can be used inside public buildings.

It uses the same connectors as Ecoflex 10 and 10 PLUS

Characteristics:

| Diameter | 10.2 ± 0.2 mm |

| Impedance | 50 ± 2 Ω |

| Attenuation at 1 GHz / 100 m | 13.49 dB |

| f max | 6 GHz |

| Euroclass acc. to EN 50575 | Cca |

Properties:

Certified according to EN 50575:2014 + A1:2016 for applications in buildings with requirements to fire

Flame retardancy tested according to DIN EN 60332-1-2:2005-06 + DIN EN 60332-1-1:2017-09

Heat release tested according to DIN EN 50399:2017-02

Vertical flame spread tested according to DIN EN 50399:2017-02

Smoke production tested according to DIN EN 50399:2017-02

Flaming droplets tested according to DIN EN 50399:2017-02

Acidity of gases tested according to DIN EN 60754-2:2015-08 (pH value > 4,3)

Conductivity of gases tested according DIN EN 60754-2:2015-08 (< 2,5 µS/mm)

Corrosivity of fumes according to IEC 60754-2

Jacket material according to DIN EN 50290-2-27 (HD 624.7)

RoHS compliant (Directive 2011/65/EC & 2015/863/EU RoHS 3)

Low Smoke, Fire retardant, Zero Halogen (LSZH)

UV-resistant

Manufactured according to DIN EN 45545-2 Table 5 R15 HL2